Product description

Our original technology significantly modifies the design process of window sections and thus allows us to manufacture a product that is improved, both in terms of its production technology as well as its shape and characteristics. On the Polish market, standard window squared timbers are manufactured as timber with a rectangular cross-section, which is then processed to obtain a required profile for our window manufacturers. This solution generates significant material losses, which is eliminated in our products.

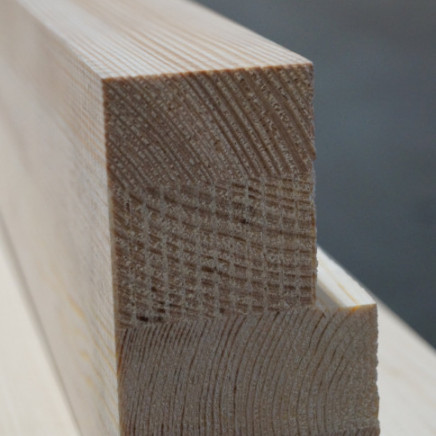

The L-shaped and T-shaped timbers are significantly improved products in relation to those currently produced on the domestic market, because due to their innovative design they assure a customer that the use of raw materials is significantly more cost effective.

The use of L-shaped and T-shaped timbers in the production of windows and doors will help reduce material losses by nearly 16% comparing to the rectangular cross section timber currently existing on the market.

This means that when buying a rectangular square timber, a window manufacturer actually uses a maximum of 84% of the purchased raw material. In the case of an equivalent L-shaped or T-shaped timber, this will be much closer to 100%.

For a standard rectangular squared timber, there is a high risk of discovering wood defects during its final profile processing. In the case of a timber profile adapted to the required window element, all defects are discovered and eliminated at the stage of gluing the laminated timber.

The L-shaped and T-shaped timbers contribute to shortening the window production process, as one of the two contour processing operations is eliminated. Thanks to this, the production time is shortened and its cost-effectiveness is improved.

Summing up, the unquestionable advantages of the L-shaped and T-shaped timbers are therefore raw material saving and eco-innovation, minimizing the risk of discovering wood defects during final production and adapting to individual customer requirements.